Raising the stock fuel pressure to account for additional boost.

In short:

Flow Rate = Duty cycle X Fuel Pressure,

Increase fuel with more fuel pressure:

The square root of (new pressure/old pressure) * stock flow rate.

Stock fuel pressure = 37PSI

Stock Flow rate = ~260cc/min

Ö(42PSI/37PSI)*260cc

New flow rate = 277cc

Simply increasing the base fuel pressure will make the engine run more rich at lower boost, and will hurt your fuel economy slightly. However, it will allow you to boost over the ~13-14PSI "limit" of the stock fuel system without running dangerously lean.

It’s a good idea to upgrade your fuel pump. The stock Z31 fuel pump is not a very high flow unit, and at higher fuel pressures it will more than likely not be able to sustain desirable flow. The Walbro 255lph unit for 240SX's can be installed, or the Z32 Twin Turbo fuel pump (I hear the Z32 pump will slightly outflow the Walbro). Fuel pump installation can be accomplished by dropping the tank or cutting a hole in the rear deck (hatch) area. Here is how someone installed it into the carrier. If you are lost, follow your Haynes manual for installation instructions.

The fuel filter on the Z31 is also more restrictive than the Z32 unit, I would recommend replacing it; a $15 upgrade. You will have to find a way to mount it, and carefully as it sits fairly close to the exhaust manifold. I noted a 1PSI increase in fuel pressure from simply “upgrading” the filter.

Now you can raise your fuel pressure, BUT an increase in fuel pressure must be monitored in some way. In other words you will need to purchase and install a fuel pressure gauge that gets mounted in the engine bay. I bought a nice Autometer unit for $26 and installed it using AN fittings from the local parts store.

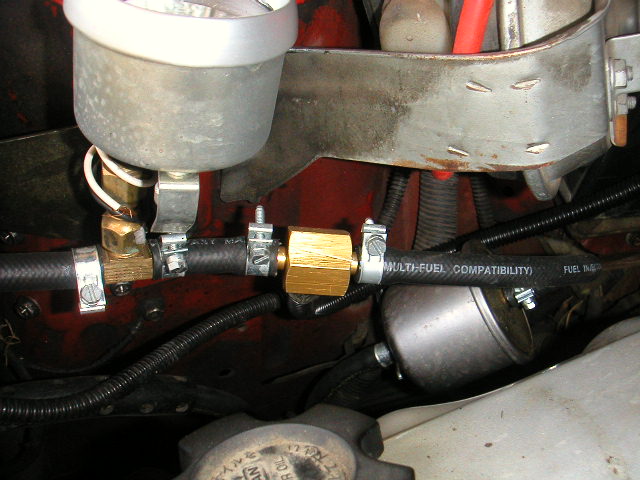

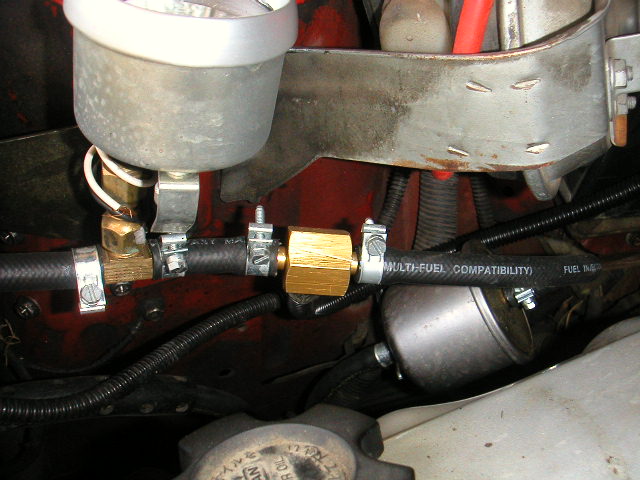

Note the Z32 fuel filter and fuel pressure gauge:

So now you can actually raise your fuel pressure and monitor it. You can crush the stock regulator carefully using a bolt and a hammer, tapping lightly around the inside and closely watching the pressure increase.

People have commented on the reliability or safety of a crushed regulator. Someone actually told me they thought it was completely stupid and unsafe because there is gas inside the regulator. While nothing is completely "safe", their reasoning should be based upon knowledge. To begin with there is no fuel in the area you are bending metal, only air. You are simply bending a little metal to get a sprin to apply more pressure, that's all. This mnodification has been preformed on countless cars with pressure regulators and similar parts just like the one on a Z31 and is nothing new.

Some aftermarket fuel pressure regulators include a gauge or a port for one as part of the unit. Some "rising rate" pressure regulators are sometimes a tricky thing to use, and in my opinion no better than crushing the stock fuel pressure regulator a little (or making it adjustable so you can take fuel pressure back down to stock since you cannot "uncrush" the stock regulator). All that MOST rising rate regulators do is raise fuel pressure in accordance with manifold pressure at a 1:1 ratio, thus compensating for the manifold pressure to obtain a proper mixture. So, you really could say the stock unit is a "rising rate" pressure regulator. Crushing the stock unit is simple, just find a bolt to lightly tap around the center of the regulator down with. This in turn puts more pressure on the spring inside; regulating the pressure higher. Avoid the air fitting and tap VERY lightly with the ignition on so the fuel pump can stay running. Monitor the increase on the gauge and keep in mind the amount of increase is all that is important. I would not go over 5-6PSI over stock fuel pressure with a stock turbo. According to wideband datalogs, an additional 6PSI should allow you to run ~15PSI of boost (on the stock T3) safely, and you are already well out of the efficiency range of the T3 compressor; any more boost is probably a waste.