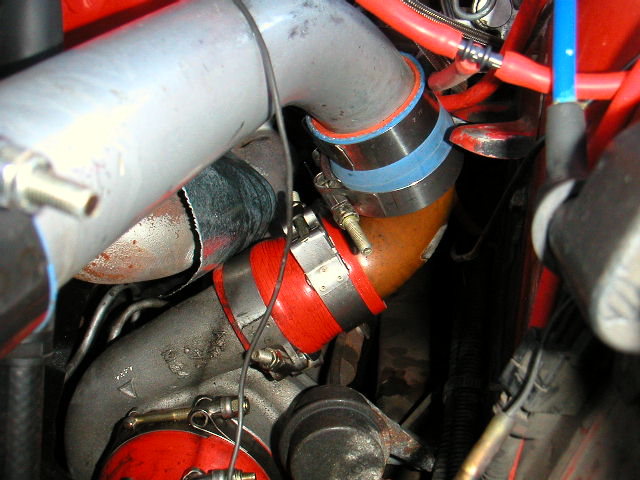

The intercooler completely nasty when I got it. I decided to clean up the end-tanks with rubbing compound so they were not so cruddy looking. I had to bend plenty of fins back, and got the thing looking acceptable. Cleaned out the oily buildup inside using brake cleaner, etc etc. The piping is 2.0 inch mandrel bent steel. There is simply a copper bend coming off the compressor housing

Pictures:

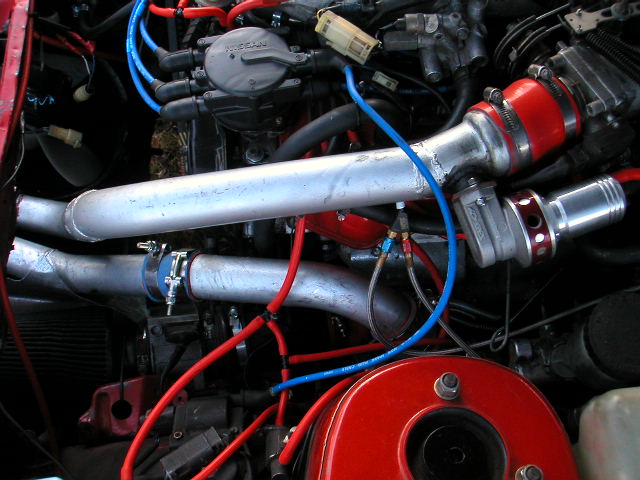

Then I spent over an hour bending all the fins straight again, that was tedious to say the least. I had to cut the inlet/outlet ports slightly shorter so the core would fit how I wanted it to under the bumper cover. It mounts using bent pieces of 1 x 1/8 inch strip aluminum. I also needed to purchase 2 90 degree bends (I wasted my money on silicone ones) and 2 converters to go from 2.5 inch to 2.0 inch piping. I know this setup is slightly less than ideal, but it works nicely nonetheless. As for how much boost I run, which gets asked all the time. I seem to be able to run about 13PSI at stock timing on 93 octane pump gas; it detonates just above 13PSI (keep in mind I have 9:1 compression). I liked to stay away from the possibility of detonation though, so I ran about ~12PSI and retard timing about a degree. I figure this gave me adequate safeguard on hotter weather, and I never heard any, even when it was almost 90 degrees outside. I believe the 13PSI limit is due to the stock fuel injectors being maxed out (or rather, the computer limiting their duty cycle). So I increased fuel pressure the easy way. Now the turbo is easily maxed out running 16PSI (considering the pressure drop through the intercooler, this is actually 14PSI at the engine), any more boost would be useless because the T3 turbo is already out of its efficiency range.

Note the copper plumbing bend, it's tight in there:

Added some driving lights, partially to fill in the holes where the stock splitter used to be:

Another issue you WILL run into after installing an intercooler is compressor stall/surge. This is caused when you are accelerating in boost and then let off the gas (IE between shifts) in turn closing the throttle plate and blocking the path of all that compressed air in your intercooler and piping. This air flows backwards into the compressor and causes a dramatic loss of velocity. In turn you get turbo lag between gears, very bad. The solution to this is a re-circulation or blow off valve. This is a valve that bleeds off the "extra" pressure between shifts. Re-circulation valves put the extra air back into your intake before the turbo, blow off valves just vent the air into the atmosphere. They are available all over the place, but I would recommend shopping around, reading reviews and then contacting The Specialty Shop if you are going to purchase one. I did not skimp and buy a cheap or used blow off valve, I spent the money and got a nice APEXi Twin Chamber Blow Off Valve. The pipe and flange it is attached to is just coated with primer to keep the welds from getting rusty.