The use of a (mechanical) Fuel Management Unit.

Be sure to also see the Z31 fuel options page.

If you just want a little extra headroom without changing injectors, what you really want to buy is called A FMU or fuel management unit. These allow fuel pressure increases other than a 1:1 ratio with manifold pressure, allowing increased flow through the injectors without raising the base pressure as much (or at all).

Question from some person: "Someone told me FMU's were bad for my fuel system. They said they had heard of a guy who fried his fuel pump and injectors using a 12:1 FMU. He said the air/fuel ratios would be all off and blow up my engine."

Answer from Jason: By simply running a FMU that raises fuel pressure too much, say a 12:1 that you cited. You are increasing fuel pressure and hence flow. Pressure varies with flow as the result of the square root of the new pressure divided by the old pressure times the origonal pressure. Stock fuel pressure is ~37PSI. So with a 12:1 ratio, let's see how much boost it takes to get to our "90PSI" limit on a decent aftermarket pump? 1lb boost:: 49PSI On a side note, if you used the FMU with a recalibrated ECU with raised TTPmax setting and adjust the fuel maps, you could probably get 350+whp out of the otherwise stock fuel system. |

FMU's I have used:

Cartech makes a nice unit that has the desired adjustable rate of gain, it runs about $200 plus shipping from most good online vendors. Many other models are available with different features, rates of gain, etc.

The formula for increased flow after more pressure is:

The square root of (new pressure/old pressure) * stock flow rate.

and 1.2734 x 260= ~331cc

so it follows...

80PSI would make ~382cc injectors out of 260cc.

Thus, you should be able to see that with an upgraded fuel pump and more fuel pressure you can get well over 300RWHP on the stock fuel injectors.

This is a legitimate way of breaking the ~260RWHP barrier of the entirely stock fuel system.

I purchased a Cartech 2025 FMU used for ~$150; the units feature adjustable onset and rate of gain. With the onset adjustment all the way in, fuel pressure starts to rise past the stock 1:1 ratio at about 6PSI. This is annoying because I would have rather had it start to rise around 10-11PSI where you would start to go lean with a bigger turbo. Nonetheless, it still worked fine. You can alsoinstall a bleeder or check valve (same thing as a manual boost controller) inline on the signal line to the FMU in order to regulate onset pressure.

Once you have the onset set, then the needle valve essentially becomes an AFR screw from there, you can adjust as needed (but will never get over high boost/low RPM richness, because there is no way to base the increase on airflow as well) for the desired AFR. Tuning with a wideband O2 is recommended, I tuned with my eyes, spark plugs, and the way it felt. A fuel pressure guage mounted outside the car (where you can see it) is a very valuable asset in determining how much pressure can be run before the bump starts to "fall off" or the internal pressure relief valve comes into play. Three problems you will run into if you go for bigger boost:

1. Fuel pump flow is not sufficient, I hear the walbro's also won't handle much over 90PSI (or 100PSI shimmed).

2. Fuel injector lockup at over 100PSI fuel pressure is somewhat likely.

3. Again, maxing out the stock AFM/ECU programming, the timing maps are off so be careful of detonation in upper RPM (500RPM and above). I had to back out another couple degrees of base timing (almost 5 degrees backed out now) to get it to not detonate at all at 15PSI. I ran the car with a little bit of race gas mixed in and found it to be noticeably faster at 16PSI, again with the fuel pump giving out at about 18PSI boost pressure.

For comparison purposes, here are some of my wideband data logs.

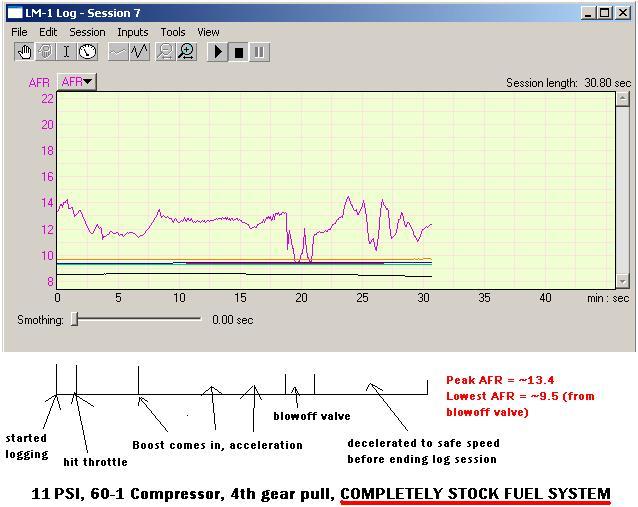

This is a pull at 11PSI with a completely stock fuel system being used with an upgraded turbocharger.

Note the dangerously lean condition in upper RPM (I did these tests with ~10 degrees of timing pulled out so I would not have to worry about detonation. While fuel consumption does increase slightly with more timing, the "tune" was close enough in the end.) This is the primary reason I would never recommend running more than 9-10PSI on an aftermarket turbo if the stock fuel system is being used!

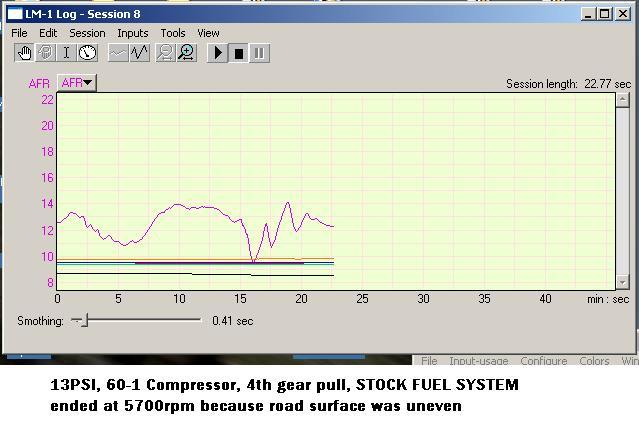

This is a pull with the exact same setup except running 13PSI. Notice the extremely lean AFR's. This is FAR too lean for any vehicle being driven under wide-open throttle, let alone turbocharged. (the run extends from 1 second to ~15 seconds in time.

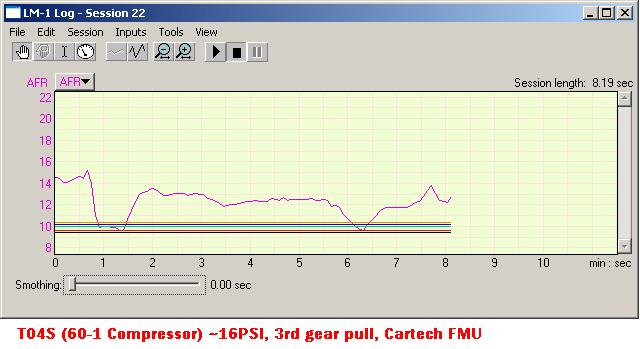

This configuration is the same, except for the addition and light tweaking of the FMU. I was able to run 16PSI boost pressure with fuel pressure maxing out around 85PSI. The 12.5-12.6 AFR is still somewhat lean from what some people like to run theirs at, but far more "safe" than at 13PSI without the FMU: