Head Work For The Nissan SOHG VG Engines

By: Jason84NA2T

- Head castings (with related port and chamber work)

- Valves (type, seat/grind specs, guides, etc)

- Valve springs and Retainers

- Camshaft(s) and Cam Timing

- Lifters, Rockers, Seals and Gaskets

- Endgame: engine tuning and performance

- Additional reading

Head work is a great way to make more power on almost any conventional 4 stroke internal combustion engine, unfortunately the majority of the work is on the pricey side unless you can do most of the work yourself. The a good step in making more power is getting the heads to flow better by porting them; making it easier for the engine to both draw air in and push it out of the combustion chamber. Engines effectively are air pumps; the more easily you can allow the engine to do its work (less pumping losses) the more power the engine will be able to produce with the same amount of fuel and air. This is a simple way of explaining the concept of Volumetric Efficiency (AKA Ev)

Note: most people look straight to porting heads to get better flow and more power, but there are several items above that both go along with and will contribute to flow and hence power gain just as much as the port work. The stock Z31 intake plenum will be a major restriction and hinder any gains made from head modifications. Be sure to consider your options for upgrading the intake plenum.

Porting: This is the process of removing material off the insides of the intake and exhaust ports in order to aid airflow through the port. Gains from porting are largely dependant on the valve seat size and shape, short and long side radius, as well as the shape of the tulip on the valve itself. Having a set of VG30 heads professionally ported can cost anywhere from $300 to $2000, depending on who does it and how extensively. A typical street/strip port job should cost no more than $1000 including assembly and before/after flow data from at least one port.

Head porting is (absolutely) one of those D.I.Y. modifications; IF you're on a tight budget AND like to learn! To get started you will need a die grinder, carbide bits, cartridge rolls, cross-buffs and a whole lot of time and patience. Die grinders can be found on eBay, so can carbide bit sets (pay attention to the size). Desirable die grinders for delicate aluminum work are rather expensive, but a novice will likely not notice the difference until they have had a lot of practice. Other materials are available from Standard Abrasives (small engine porting kit and cross buff kit, sometimes these are also on ebay). The last things you will need are a book and a spare, junk head to practice on. Read the book, practice on the junk head. There is also a lot of good information on the net, use GOOGLE! Actual port work is far beyond what most people envision (and somewhat outside the intent of this guide); it takes lots of practice to yield promising and consistent results. When you pick up the grinder for the first time to practice, you will only begin to appreciate the art form which most experienced engine builders take decades to master. Once you think you have the hang of it, I would recommend finding a spare set of heads for your engine (usually $50-100 at a junkyard). If you decide to port your own heads, I cannot overemphasize the importance of reading information on this topic before starting a practice set.

After the porting work is completed, smoothing with the cross-buffs OR Dremel Part #511 and a Dremel tool will give a nice smooth finish on the port surfaces to prevent deposits. I found the Dremel part to be slightly superior to the regular cross-buffs, mostly on account of its smaller size; it was more versatile:

Dremel Part #511

Intake Port View #1

Intake Port View #2

Intake Port View #1

Intake Port View #1

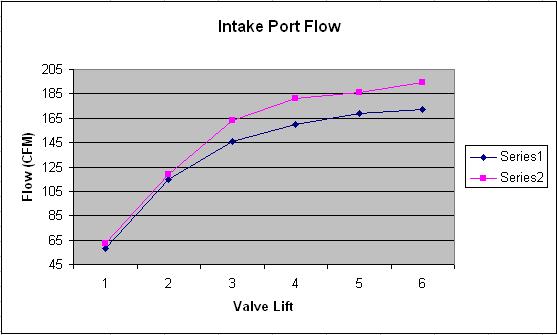

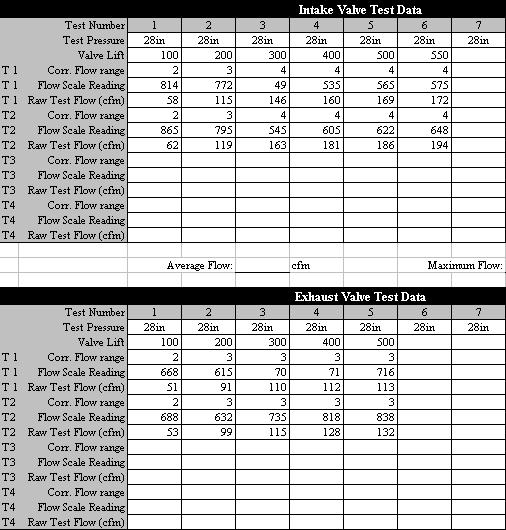

This port work was then improved upon on the exhaust side by a local engine builder with many years of experience doing custom ported cylinder heads. The difference was visually massive, but I'm not entirely sure how the flow was enhanced. Regardless (and curious), I gave him another set of heads for another VG I was building and asked for flow data on both intake and exhaust before and after porting. I had hoped for finer increments from .100 to .500 valve lift (about as much lift as people run on VG's) but flow bench time is very expensive. For a turbocharged vehicle you should pay particular attention to the exhaust flow. Think about it this way: the engine is being force fed its intake air, it still has to expel the additional exhaust gasses itself, robbing power.

These numbers can be improved upon with further modification. This is a basic porting job:

Flow data for stock and modified early VG cylinder head

Graphical images created from flow data (in CFM) shown below.

13% peak additional intake flow, 17% peak additional exhaust flow

The interesting thing to note is no loss (and in fact a gain) of flow at .100" and .200". We can assume our very low lift flow numbers did not change much, if at all.

Using a camshaft resulting in a .480" valve lift, we can see how much that additional valve lift is going to air our overall airflow and hence power. Also consider that the valve spends more time at lower lifts and that difference is not quite as exciting, but still you should see how a different cam grind and ported heads go hand in hand with one another for making power. That's not at all to say you will not gain power with a stock pair of cams and similarly ported heads.

Combustion Chambers: Smoothing the inside of the combustion chamber will help eliminate hot-spots that can cause detonation and pre-ignition on high-boost turbo or high compression N/A engines. It will also reduce compression very slightly as material is removed from the chamber. You should pay careful attention to the machined areas of the cast aluminum chamber around the valve seat inserts. There is usually a substantial small ridge which can develop hotspots and does nothing to help airflow past the valve seat. If you have an old set of stock valves and no use for them, grind the margin thickness away until the valve covers only the seat area. This will allow you to smooth the chambers and pay attention to the areas around the seat inserts without worrying about damaging the valve seat. Use Dremel Part # 511, (or a similar crossbuff) to smooth the chamber, then work on the chamber around the valve seat insert working it down to the same level around their border.

Remove margin thickness |

|

|

|

Continue until surfaces are completely smooth and ridge around seat insert is reduced. |

|

Heads with chamber and port modification; ready for jet washing.

Left: Ferrea intake valve. Right: stock Nissan intake valve.

Left: stock Nissan exhaust valve. Right: Ferrea exhaust valve.

Valve Springs:

| Brand | Seat Pressure (as tested) | Type | Cost | Comment |

|---|---|---|---|---|

| Stock Nissan | 54 lbs. |

Double springs | ~$150 new cheap used |

Already in your car! Good condition stock valve springs have been shown to work well even on modified engines. |

| Jim Wolf Tech | 61 lbs |

Single "harmonically tuned" coil spring and replacement shims | ~$130 | Seat pressure is with JWT spec shim and no inner spring. With addition of stock inner spring, seat pressure will be 71 lbs. |

| Schneider Engineering | 110 lbs. |

Double springs | ~$85 | Most likely the best price/performance you will find. |

| Paeco Developments | ? |

Double Springs | ? | Anybody know if they still make them? |

| ISKY | ? |

? | ? | Anybody know if they still make them? |

------------

------------

JWT spring and replacement shim. - - ----- - -Schneider valve springs.

Spring Retainers: Another item that is both frequently looked over and hard to find. A lighter retainer will reduce the valvetrain weight and allow the spring to make better use of its rate in keeping the lifter in contact with the cam lobe and rocker at high RPM. If you buy aftermarket retainers, ONLY titanium should be used. Aluminum spring retainers can deform and allow the keepers to pull through the retainer, dropping the valve and possibly ruining your valve, piston and head!

VG30/VG33 Camshaft Information Page (link)

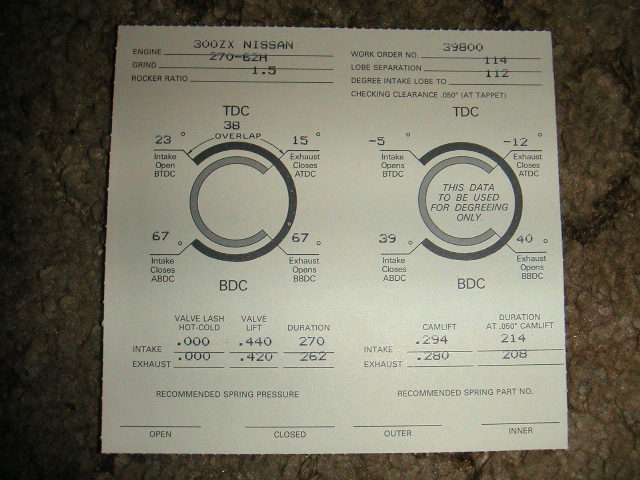

Freshly reground Nissan VG camshafts.

Typical Cam Card

When cams are re-ground, they have a smaller base circle in order to allow new degreeing and lift on the lobes. On most engines you have to make up for this somehow, otherwise there will be slop in the valve-train. With most VG cam grinds, there was a small enough reduction in base circle to be covered by the adjustability of the stock hydraulic lifters. Keep in mind that when JWT says their S2 cams are the "biggest you can fit in the head without modification" this is based on a stock base circle so you can fit "bigger" cams if they are ground with a smaller base circle. For the sake of explanation imagine a cam lobe; then simply shrink it by 10% or so. When you reduce the base circle your cam lobes are going to be "shorter" at their peaks despite being the exact same lift. The lifters will "pick up the slack" and account for the reduction in cam lobe size. Now imagine you reduce the lobe size by .095" but leave the peaks at the same height; you've just increased lift by .095"! This means your stock .385 lift cams would now be .480" lift.

Keep in mind that degreeing is generally more crucial to making power than lift is. If you ONLY increase lift and keep the stock degrees you might see a small gain (for sure under 10HP). A good example of this is the ford 302 (Mustang 5.0) V8. By changing the rocker ratio, only valve lift is changed. On that engine, with 16 valves, the power gain was about 7RWHP on average. Yes, 7 HP. The same engine with a performance camshaft (which has different durations) made another 23RWHP.

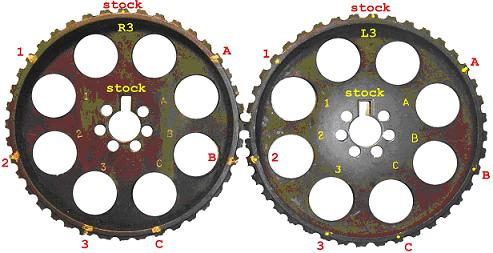

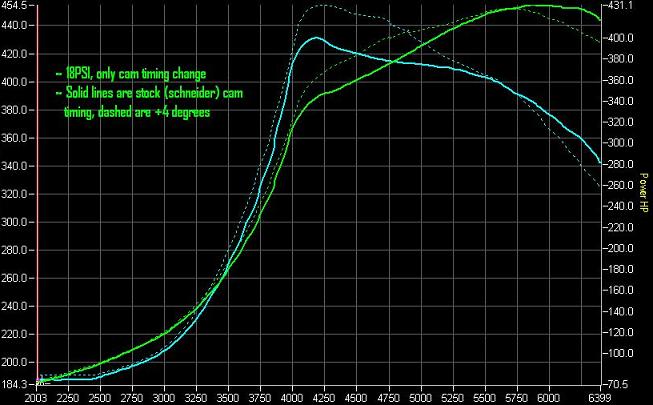

Cam Timing:

Adjusting cam timing moves torque and horsepower peaks up or down in the RPM range. It can help you dial an engine in for the type of use you intend, or for making maximum power numbers, or maximum vehicle acceleration.

Simple Rule of thumb:

Advancing cam timing yields more mid-low range torque

Retarding came timing yields more top-end horsepower

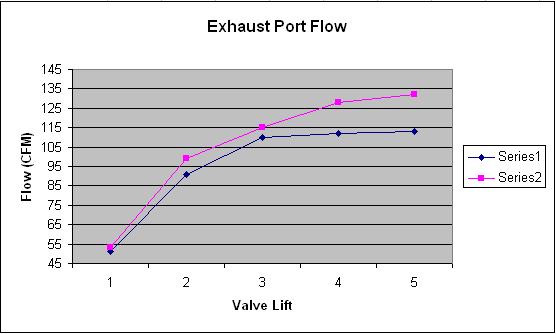

"Morgan's Adjustable Cam Gears"

"Russ' Adjustable Cam Gears"

There are two types of adjustable gears currently available for VG's. The less expensive type simply have new holes drilled around the hub for the cam dowel to go into. This allows a fixed change of +/- a certain degree range selected by whomever makes them. The more expensive but much more desirable type use a replacement center hub to allow the gear to be rotated in 1 degree increments +/- to the user's desired setting. This type of gear will allow you to quickly and easily dial in a car on the dyno to yield the shape of the power delivery you desire most.

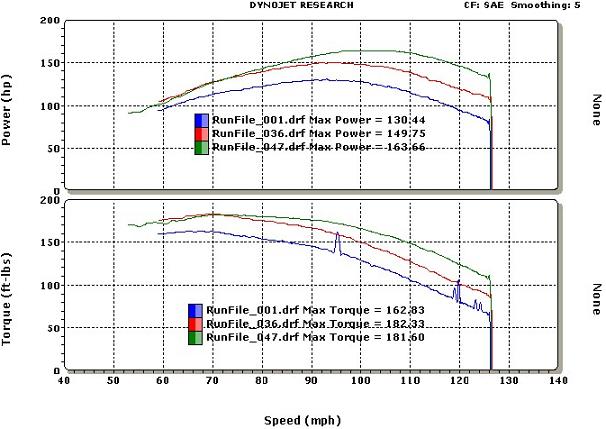

Adjustable cam gears are a highly useful component on a modified engine with both stock and aftermarket cam grinds. Below is a dyno graph from my car at 18PSI boost pressure with only a cam timing change of +4 degrees between pulls. Note the staggering difference in torque from 4000 to 5500RPM:

Dyno Graph showing changes from advanced cam timing (aftermarket cams).

Another dyno graph, this time from a non-turbocharged VG30 engine and retarding cam timing instead of advancing. The only other modifications to this engine were intake piping (not plenum), exhaust from the engine back, and fuel delivery. The lowest (blue) line is a stock baseline, the second (red) line is from the other modifications, and the top (green) line is the other modifications plus a cam timing retard of 5 degrees.

Dyno Graph showing changes from retarded cam timing (stock cams).

Lifters, Rockers, Seals and Gaskets :

Lifters: Resurface them or replace them. New Nissan lifters are under $10 from nissanparts.cc

You can have them resurfaced at a machine shop or do it yourself. To resurface them yourself, simply place some 1000 grit sandpaper on a very flat surface and rub the cam surface of the lifter evenly across it. Then rotate the lifter a few degrees every few seconds, causing the surface to be sanded evenly. Repeat until you have a mirror-like finish. Re-surfaced lifter:

Resurfaced Hydraulic Lifter

Rockers: When you install the rocker shaft, make sure to do it very slowly in many stages so you don't bend the shaft. As stated before, follow your Factory Service Manual or Haynes manual to the letter for head installation! Aftermarket rockers listed specifically for the VG seem to not exist. While I'm sure there's a part out there that can be modified to fit and work on the VG, I have not found it.

Seals: The valve and cam seals should be replaced; OEM, Fel-Pro and Victor-Reinz are quality replacements, most any aftermarket seal (cheap ones included) will last 50k+ miles without issue if they remain properly seated. When installing valve seals, be sure they are fully seated on the head or they could work free over time.

Gaskets:

- Nissan OEM head gaskets have been used on engines making over 700HP and will run you ~$40 each from a dealer, or ~$30 each from nissanparts.cc.

- Victor Reinz head gaskets (at in the non-w series VG30ET complete set) are a stainless steel center with composite lining on either side. These gaskets, in my opinion, are probably the best you can buy without going for a true MLS (multi-layer stainless) head gasket, which are not available anymore anyway.

- HKS and GReddy MLS head gaskets are extremely rare and hard to come by. Expect to pay easily $400+ for a pair if you can find them.

- Regular Fel-Pro head gaskets seem to be inferior to the other brands. I have heard of and replaced more blown Fel-Pro head gaskets than any other brand.

- Factory head bolts can be re-used and are proven reliable on modified engines. This may have something to do with the VG having 13 head bolts per side :-) Whichever head gaskets you use, be sure to follow the factory service manual's procedure for head bolt tightening EXACTLY, using a quality torque wrench.

Victor Reinz headgasket construction: steel center layer with composite lining.

Endgame: Engine Tuning and Performance

I am a FIRM believer that the performance enhancement yielded by any form of modified engine airflow can only be partially realized without modifications to the engine control system.

Ported VG heads with many modifications.

While MAF based EFI systems like that of a stock Z31 can adapt to the changes in volumetric efficiency (which makes them superior to speed-density systems in that respect), the engine will now have slightly different needs than the system was originally programmed for. For instance, an idle air/fuel ratio of 14.7 and 20 degrees BTDC ignition timing may be perfectly fine on a stock engine, but the modified engine may idle better and respond off idle faster with a 13.5 air/fuel ratio and 22 degrees of timing. This is going to be true for all engine speeds, meaning changes to fueling and ignition timing over the entire map all also be needed to optimize the additional power potential. For information on factory EFI and aftermarket or modified fuel systems, please see the link below:

Modified VG30ET cylinder head assembly (less lifters and rockers) .

Schneider valve spring and Ferrea valve sets.

Modified VG30ET cylinder head assembly with Ferria valves.

http://www.nissanperformancemag.com/december03/nerds/

http://www.nissanperformancemag.com/january04/nerds/

http://www.chevyhiperformance.com/techarticles/89678/

http://www.sportcompactcarweb.com/tech/0009scc_ssbbpart4/