By: Jason84NA2T

So there sits your Nissan 300ZX Turbo. The perennial sports car of it's day. A smooth, comfortable high speed touring machine. Beautiful, sleek, and powerful. The yearnings for more power will soon set upon you, with DSM's, Mustangs, Corvettes and Porsches that are just that much faster.

Many people consider engine swaps at this point; considering spending thousands of dollars to put another engine into their car. The fact is the VG30ET engine already in your car is more than capable of making big HP numbers on stock internals, and even more power with parts like aftermarket forged pistons (more on this later). To replace the engine with something less capable, for more money, is simply not logical.

Most people replacing the VG30 with something else are doing it for the “wow factor” or to gain additional displacement. The VG30 is a time-tested engine that was overbuilt from the factory and is capable of making upwards of 500 crank horsepower on entirely stock internals. This very same engine was used in the Electramotive (later to become NPTI) GTP ZX-Turbo (image coppyright Obin Robinson, for more GTP pictures please go here: http://obin_jess.tripod.com/gtp.html) that dominated the IMSA GTP races in 1988 and 1989. This modified SOHC VG30 engine, with extensive race prep and arranged in qualifying trim (with no restrictor plates) it was able to produce up to 1000HP. Putting the other reasons for Electramotive’s sweeping victories aside, the engine proved to be both robust and fairly reliable at those power levels.

This FAQ covers the 84-89 300ZX Turbo: what to modify, how to modify, when to modify and what to expect from the modification. Most of this knowledge is based upon first hand experience with modifications on street driven Z31's, not race cars. This FAQ is purely focused on making power. Clutch, transmission, drive shafts, differentials, axle shafts, suspension, wheels and tires are all outside the scheme of this FAQ. Most horsepower numbers will be for Rear Wheel Horsepower (RWHP), with notable exceptions being for engine airflow and volumetric efficiency relating to crank HP numbers. Just so you know, a stock turbo Z has around 170 rear wheel hp.

Available parts: Many companies have made parts for the Z31 over the years. HKS, GReddy/TRUST, APEX'i, CarTech, Spearco, among others have produced performance parts in the past, but very few are remaining today. Much of the modification you may want to do requires some thought and design to actually complete. The Z31 is not a car you can simply buy a bunch of parts for and make fast. Like many other cult cars, there is an extreme lack of available performance parts; mostly because of the extreme lack of people willing to buy those parts at fair prices. If you want a car that you can buy dozens of performance parts for, I suggest you sell your Z31 and buy a Honda Civic.

Supporting modifications: Many people fail to understand that there are supporting modifications needed to gain power from other modifications. An engine is a system of interconnected parts that rely on one another to work to their potential.

A stock 300ZX has almost the most basic turbo system available.

(how to read and understand compressor maps)

The T25 is pretty much worthless from a performance standpoint. The only advantage it offers is lightning fast boost response. This turbo is a grossly undersized unit for a 3.0L V6 engine. You can upgrade to a T3 by obtaining the T3 turbocharger assembly (with wastegate actuator), T3 exhaust elbow, turbo to throttle pipe, inlet pipe and associated water and oil lines.

There is no stock intercooler at all. There is no compressor bypass valve or blow-off valve of any kind. The turbocharger uses an internal (integral) wastegate assembly to control boost, along with an external pop-off valve (not the same as a bypass valve), which on the front passenger side of the upper intake plenum. The air charge pipe (1) runs directly from the turbocharger to the throttle body; a little over a foot of total length.

Why is the system so simple? Well, simply put it was all they needed when the

car was produced. A stock 300ZX Turbo, when it was released in

The very easiest and biggest gains for the money involved are the following steps 1-4, and these steps (if done well/correctly) also "get what you can" out of the stock equipment. You should buy an aftermarket boost gauge and install it before even THINKING about turning up the boost. Steps 1 and 2 can be considered supporting modifications for step 3. You can really do those 3 steps in any order, but this is the recommended order. All modifications will have a rough HP gain estimate and will vary based on the amount of boost run and condition of stock equipment. This should be taken as just that, an estimate, as each modification will yield more or less power depending on the particular car and parts used.

The exhaust should always be the first step on any turbocharged car. The Z31 Turbo exhaust is 2.5" from the factory, but it has some design areas that are not good for performance. The stock downpipe has an area with a much smaller diameter in order to clear the transmission cross-member. The catalytic converter is acceptable in terms of flow, but becomes a major flow restriction at raised boost levels. The cat-back exhaust portion also has a fair design in terms of flow, but the muffler is very restrictive.

Muffler design is also another key element to exhaust flow. The best flow will always be attained by a straight pipe, so "straight through" style mufflers are usually the best flowing mufflers available; bar none.

If you are sure you can get away with it, remove your cat, or punch it out. The metal matrix inside is coated with platinum, and is somewhat hard to break out, so you might be better off selling it as scrap and buying (or making) a test pipe. Of course, this is illegal for use on public roads.

For the un-motivated; simply having a pre-made exhaust system installed should never cost more than about $75, at any reputable muffler shop. HKS and GReddy both used to make exhaust systems for the Z31, but both are long discontinued.

SOME VENDORS:

1. Certified Muffler:

Quality complete exhaust systems available

in 2.5" or 3" aluminized or stainless steel. Pieces can be ordered

individually or as a complete system. 3" system with no cat is a little on

the loud side, but is still entirely tolerable. Good fitment and quality

mandrel bends. 3" system not only offers great performance, but also

weighs almost 16lbs less than a stock exhaust. www.certifiedmuffler.com

2. Dynomax:

Inexpensive cat-back system with 2.5" aluminized steel piping. Slightly

restrictive muffler for modified turbo cars, not loud at all and has a very

nice tone. Good fitment and quality mandrel bends. Not available factory-direct; can be ordered through places such as summit racing. www.dynomax.com

3. Custom Exhausts (link):

Most 'custom' systems from a muffler shop will end up being 'crush' bent piping.

If you cheap out and insist on going this route, make sure the piping is 3"

or it won't flow any better and will only be louder than the stock system. The exception to this is

assembling your own system from mandrel bends. While this takes a lot of time

for cutting and welding, you can build a very nice exhaust for much less money

than a retail system. Be

prepared to locate a flange and donut gasket for the exhaust elbow, you may have

to find a flange that is close in fitment and slot the holes. Certified

Muffler will sell you the flanges and gaskets used on the Z31 systems if you

ask nicely.

4. No exhaust/open dump from elbow:

Free, very cheap to do and the least restriction of all. Considered too loud,

but sounds bad-ass when the car is under boost. Can cause the undercoating in

the transmission tunnel to burn off, can also start other fires. Recommend

installing a short pipe to extend off the turbo elbow closer to the ground.

Recommended for off-road use only; you may be pulled over and given a ticket for

a noise violation.

Stock Air Box: The stock air box has a "snorkel" bit on the end which should be removed for best airflow. The air box does not flow poorly, it's actually about average with that snorkel removed. A drop-in K&N filter can be purchased that is very easy to install and will provide roughly a 1-3 HP gain from using a regular paper filter.

Aftermarket cone filter in stock air box location: This has shown a gain of 3-6RWHP at various boost levels depending on the filter used. This is the most popular method, but many people locate the filter elsewhere.

SOME FILTER TYPES:

1. Team Green cone filters: ~$40

2. K&N Fuel Injection Performance Kit (FIPK): ~$ 120

3. Universal K&N cone filter: ~ $50

Rich tells how easy it

is to install the bare filter and save yourself $100 over the

"FIPK" system, which is the same thing.

Re-located filter and re-designed turbo intake setups: People have done all sorts of things to give the intake a little better routing and/or cooler air. The inlet to the turbocharger sits directly behind the drive's side engine isolator. In order to clear the mount, the intake takes two sharp 90 degree bends directly before the compressor inlet. This is a less than ideal setup, and becomes further complicated when an aftermarket turbo is installed what has a larger compressor inlet. The possibilities are only limited by space and your ability to fabricate parts.

Increasing the boost is the single most effective means of making additional power on almost any turbocharged car.

With an aftermarket intake, exhaust and boost controller fitted, significant power increases can be realized by simply turning a knob. However, it's not entirely that simple. As boost pressure is increased over the stock 6.8PSI, the intake charge temperature increases dramatically. When your intake air is hot, the likelihood for detonation increases. High octane fuels are designed to resist detonation. If you plan to go more than 1-2PSI over stock boost, run higher octane fuel than the factory recommended 87 octane. To be safe, I'll just say 'run 91+ octane premium gasoline if you raise the boost'.

Internal wastegate: As stated earlier, the turbo Z uses a integral wastegate in it's turbocharger operation. This is basically a 'valve', that bypasses exhaust gases past the turbine in the turbo, limiting how fast the turbine can spin, thereby limiting how fast the compressor can spin, thereby limiting the boost. The wastegate actuator is a small device that moves the wastegate lever itself. The actuator is not the wastegate itself, it is merely part of the wastegate assembly. The actuator is fed a ' boost signal', which is simply a hose returning from the compressed side of the turbo carrying the amount of boost currently present in the system at that point. The wastegate actuator starts to open the wastegate at about 3psi, and is fully open by 7psi, limiting boost to the rough factory preset of 6.8psi.

To modify the amount of boost available, and set a new maximum boost level, the wastegate signal hose is partially blocked or redirected to atmosphere (out of the system), or back into the intake system somewhere. This essentially fools the wastegate into seeing a lower-than-actual boost level, and the wastegate stays closed longer, the turbine spins faster and the compressor makes more boost. This is how boost is controlled.

Pop-off valve: This is a small valve located on the front passenger side of the upper intake plenum. When boost exceeds ~8PSI this valve will open and vent the excess pressure to atmosphere. This is a safety device that was installed to keep the boost in check in case of a failure of the wastegate. You can easily defeat this device by unscrewing it from the plenum with a large pair of vice grips or a pipe wrench and plugging the hole with a 1" NPT plug available at any Home Depot or similar hardware store for about $1. Some people have said that this leaves you with no protection from an overboost situation, which is true (at least at this point), and recommend installation of an adjustable pop-off valve. Greddy makes a unit (pic) for roughly US$100. You can also modify the stock pop-off valve to hold more boost.

Boost control: There are two main types of boost controllers available on the market; electronic and manual.

SOME UNITS:

1. Electronic boost controllers

2. Manual boost controllers: $20-$100

More brands than can be listed. These are

basic units that do the same thing as their electronic counterparts, except

using only mechanical parts. Highly recommended for the budget-minded person.

Because of a common problem called "boost spike", some cheap manual

controllers can cause, they have a somewhat bad reputation with some people.

Boost spike with a manual controller is usually only a problem with internal

wastegates, and is usually caused from having too much hose between the

controller and the actuator. There are two basic types of manual controllers:

In general, the electronic boost controllers will make for faster boost response and more stable boost control, but at low boost levels (under 12PSI) manual controllers will work just fine and save you money.

HOW MUCH BOOST CAN I RUN? - The number 1 question of all time on Z31.com

This question is hard to answer without explaining some things first. Essentially you are trying to avoid detonation, which is the primary cause of damage to turbocharged engines. Detonation is not your friend.

Detonation is caused by a number of things, including but not limited to:

In a controlled burn, a single flame front is generated at the spark plug and proceeds outwards from the plug, burning the fuel and transmitting its chemical energy (in the form of pressure) into the mechanical energy via the piston. Detonation consists of multiple flame fronts colliding inside the combustion chamber; an uncontrolled combustion event. When these fronts collide, the pressure is not controlled and focused as it is in a controlled combustion event. This can cause unfocused, instant and huge increases in cylinder head pressures, which blows head gaskets, breaks spark plugs, pistons or anything else. Commonly confused with detonation is a condition called pre-ignition.

Lean mixture: When you raise the boost, you must compensate with more fuel. You can only put in as much oxygen as you have fuel for in order to maintain a "safe" air to fuel ratio. Also, consider that the air varies density with temperature. The colder it is outside, the more air your engine is effectively taking in per cycle. The stock fuel system can only support roughly 12-14PSI of boost pressure (using a stock T3) before the air to fuel ratio (AFR) rises to an unsafe level.

High intake air (charge) temperature: A simple law of thermodynamics is when you compress air, the air temperature will rise. When you compress air with an air compressor operating out of its peak efficiency range, it causes the air to heat even more. (Read the next section for more information on lowering charge air temperature.) Because of its design, the Garrett T3 turbocharger has a compressor which is going to be most efficient on a 3.0L engine at the stock 6.8PSI boost setting.

Limits of compressor efficiency: Greatly related to the intake air temp. As a compressor extends further and further out of its efficiency range, it heats air more and more as it is forced to build additional boost. Chassis dyno results have shown that the Stock T3 will continue to make additional power with additional boost until about 15PSI. In a test on one car, 16PSI power was shown to be making only 4hp more than at 15PSI, and at 17PSI there was actually a very slight loss of power. At boost pressures this high you are over-spinning the turbine anyway, and this will most likely cause premature bearing failure. More boost does not mean more power; better boost (from a compressor operating efficiently) means more power.

Fuel octane rating: Octane is a component of gasoline derived by two methods,

then averaged (R+M/2). Typical pump gas in the

Too much ignition timing advance: The stock timing maps in the ECU are designed for everyday use with stock boost and regular gas. If your base timing is advanced, the entire map is advanced. Be sure your engines timing is set properly using a timing light.

To try to answer the 'How much boost can I run'

question, you must really look at your individual situation.

What condition is your engine in? How hot (or

cold) is it outside? What octane of fuel are you running?

If it's not too hot out, you're running high octane fuel and your engine is in good running condition you have NO problem running 8PSI, almost definitely no problems running 10PSI, and if your careful to listen for detonation while turning up the boost you can probably run as much as 12PSI without detonation. If your engine has lots of buildup in the combustion chamber or advanced ignition timing, you might not make it past 10PSI without detonation. Remember, if you're running in boost for long periods of time (3rd or 4th gear pulls), or you just like to drive at wide open throttle with the music cranked up, you may want to keep your boost on the conservative side to avoid unwanted engine damage.

If you're lucky and live in an area where you can get 93 octane fuel, you may even be able to run as much a 13PSI before adding an intercooler. Be aware that you are very near the limits of the stock fuel system with this amount of boost.

"But wait, don't we have a detonation sensor?"

Yes, All turbo Z31's are equipped with a detonation sensor from the factory. Unfortunately, it is mostly useless because the ECU disregards the detonation sensor feedback when the engine is in boost. Why Nissan/JECS designed it this way is beyond me.

Intercooling is not a new concept, it has been around almost as long as turbochargers. An intercooler is really a "charge air cooler"; it is the device responsible for lowering the temperature of the intake air to allow the engine to make more power, run more boost, and/or keep detonation at bay. The job of any charge cooler is simply to reduce the temperature of the inlet air, which is usually quite high due to the compressor. What are commonly called intercoolers are really aftercoolers, because they cool the air in the system after it has been compressed (by only one compressor). I have seen true intercoolers in use on tractor pull rigs; some of which run both a turbocharger and a supercharger, with an intercooler in between. However, the commonly used terminology is intercooler and that's what I will be calling them here.

One of the theories of gases states that as pressure rises so does temperature. Along with creating higher pressure, the turbocharger's compressor also increasees the temperature of the inlet air dramatically. Sustained high boost can sky rocket the intake charge temperature. With a stock T3 at 6.8PSI, boost settles at ~110ºF. Running pressure up to12PSI, jumps the temperature up to 280º (at 70ºF ambient). High inlet temperatures can cause severe detonation leading to costly repairs. This is why above 8 PSI, an intercooling device is recommended.There are a few types of intercoolers:

Air to air intercoolers: This is by far the most common approach to cooling the charge air. This is an intercooler assembly made to exchange heat between two bodies of air. They are mounted in front of the radiator, and cool the charge air using the ambient air that flows through the core.

Air to water intercoolers: This is an assembly that uses water as a cooling medium. The water is pumped through the core to cool it, and through another radiator outside of the car to keep the water at ambient temperature. Primary advantages over air to air intercoolers are small size in the engine bay, and (if properly designed) less volume, less pressure drop, and higher efficiency. Another plus is the ability to add ice to the coolant reservoir to make the core even colder than the ambient air. The down side is the additional cost, complexity and weight of the water in the system.

Another form of cooling the intake charge air is the use of Water/methanol/alcohol injection. A mix of water and methanol is injected into the air stream in much the same way nitrous is, but purely for the evaporative cooling effects on the air charge. There have been mixed results and inconclusive data about the actual gains water/methanol injection can produce. Many users swear that it is a viable solution for reducing hot intake air temperature. While many people remain skeptical, water/methanol injection has been used in some turbocharged race cars, but only as an extreme measure during hot, long-staged, events where the cars will be driven under boost for long periods of time. The advantage is simplicity: no pipes or cores to add, just a nozzle that needs to be welded into the intake tube before and throttle body and a high-pressure pump to spray the water/methanol mix which can be stored in a reservoir almost anywhere in the car. Cooling Mist, and many other companies offer universal water injection systems that you can install in an afternoon.

Nitrous is another way to cool the intake charge. When nitrous expands from its 800+PSI liquid state, the cooling effect is very large. Running even a 40hp shot can drop intake temperatures 100º+F. Like water injection, nitrous would need to be tuned appropriately and the tank level monitored regularly.

SOME OPTIONS:

1. HKS Intercooler

System (pic): ~ $1200

Comes with a efficient Air/Air assembly, all

associated 50mm (2.0") piping, a compressor bypass valve (HKS

standard type). Assembly is around 70% efficient, with 1.5psi pressure drop.

One small problem with this system is the fact that it goes under the radiator.

People with lowered cars have crushed their piping going over speed bumps.

2. Spearco Intercooler

System (pic): ~$1100

Spearco is a dedicated intercooler

manufacturing company. Very large, very efficient Air/Air assembly, steel

piping in ~58mm (2.25"), no bypass valve included. Assembly is around 80%

efficient and less than 1psi pressure drop. This is considered the

best commercial intercooler system for the Z31.

3. Custom Intercooler Systems (link): ~$300-800+

This is by far the most popular option as the

above are both expensive and hard to find. It will take some planning, but is

not a hard task to accomplish.

Things you will need to do to make a custom intercooler system for your Z31:

With the previous items installed, your engine is making the most of the factory equipment. The fuel system and turbocharger are at their safe limits for performance. Depending on many factors, this limit will most likely leave your car between 240-260RWHP. The rest of this guide extends into an area of greater complexity of modification.

Bear in mind that an engine is a system. As stated before, supporting modifications are required to realize reliable and safe horsepower gains. Do not just spend money on parts to throw at your car. Rather, I would suggest doing some research to make an informed decision on each part you purchase.

At this point things start to get more complicated and well beyond the scope of this FAQ. You must be very careful with the parts you decide to buy; at this point you are probably already pushing the stock turbo and fuel system configuration on your car. At least a very simple fuel system upgrade should be done before, or at the same time as a turbocharger upgrade. It would be very easy to go out and spend $2000+ on some type of aftermarket fuel system while overlooking the more economical options available

FUEL SUPPLY AND PUMPS: Flow vs. Pressure is the common theme for fuel pumps. The more pressure a pump has to sustain, the less flow it can provide. The reverse is true as well. The more flow is desired from a pump, the less pressure it will be able to sustain. More information on fuel pumps here (link).

Stock Z31 pump: Not adequate for performance applications because it cannot support high pressures or high flow. If you want anything over ~280RWHP safely, you MUST upgrade your fuel pump.

Z32TT and Walbro 255lph HP Pump: Capable up to 500rwhp of fuel. Inexpensive and easy to install in place of the stock fuel pump. The walbro units can be found on eBay for as little as $90.

Inline pumps: Many varieties made by Bosch, MSD, etc. These can support a wide range of fuel and pressure requirements. Widely regarded as the single best pump for the money is the Aeromotive A1000, which can support 800+HP worth of fuel in forced induction applications.

Fuel supply configurations: As opposed or in addition to buying a single, expensive fuel pump to support your fuel needs, there are a few configurations which people have had very good results when put to use.

FUEL INJECTORS AND RAILS:

There are two styles of fuel injectors to go along with the stock rails used on the VG30ET. The early engines (84-85) had top-feed fuel injectors, and the later engines (86-89) had dual/side feed style injectors. The most popular method of upgrade is to use the early (top feed) fuel rails with higher flow top-feed injectors from another car with the same style injector (type 5, hose barb fitting). There are hardly any aftermarket side-feed injectors, and none that I know of that will fit the Z31 rails. For top feed style, the most popular replacement injector are those from a 1975 Mercedes Benz 450SEL, among other cars. They are rated at 420cc/min flow rate at 37PSI fuel pressure and are sold as Bosch: 280150036 Standard Ignition: fj118 and Borg-Warner: 57512. You will need to shave the injector connectors down slightly to get the stock connectors to fit; be sure the connectors are held securely to the injector. These injectors will get you to well over 400rwhp before they are maxed out.

What tends to be a big complication is the fact that most vehicles use o-ring style injectors instead of the hose barb kind the Z31 does. Some 11mm import o-ring type injectors can have a 3/8" fuel hose squeezed over them if the o-ring is removed some people file down the o-ring area on the injector to fit a 5/16 (stock diameter) fuel hose. Fuel injection hose clamps are then used on both the rail and injector hose barbs to secure and seal the hose. Although no complications have been reported, for safety reasons I cannot recommend this method. As of 10-07, high performance fuel rails for 11mm top-feed injectors are available from Z31parts.com; you will also need up upgrade your hoses and fuel pressure regulator.

ENGINE MANAGEMENT:

Tuning and real-time modification of parameters in the 88-89 ECU: With some work you can make the system accommodate almost any injector or airflow meter on the market. Info here.

AFC and other MAF intercept type devices: Used with larger injectors, these devices intercept and modify the signal from the airflow sensor in order to "fool" the ECU into using a lower injector pulse width per amount of air.

E-manage Ultimate and other "advanced" piggyback devices: These work much like the above AFC devices, but they have their own fuel and timing control harnesses so they function much more like a standalone than a standard AFC.

Additional Injector Controllers: Just like they sound, these devices control an additional fuel supply through the use of additional fuel injectors. SDS, HKS, and others make these type of devices.

Standalone Engine Management Systems (

Mechanical FMU: These are sometimes called 'Rising Rate' pressure regualtors, what they do is increase the fuel at a ratio higher than 1:1 with boost. They are useful, but a bit of a band-aid method, you are essentially 'fooling' the stock computer, and left trying to 'tune' the AFR yourself. This additional pressure squirts more fuel per pulse thru the injectors. Pretty Cheap: ~$200US for a typical mechanical FMU.

HKS PFC F-CON and GReddy Fuel Computers: Old-school AFC-like devices that plug in and change the the fuel delivery curve at certain RPM points. These can allow the injectors to flow more fuel by raising the duty cycle, but are still restricted by the physical size of the injectors. These devices are completely and ridiculously obsolete. If you have one to sell, put it on ebay and hope someone is stupid enough to buy it.

JIM WOLF 450HP (3BAR): This company will modify and re-program your stock ECU (computer) for one that is recalibrated with dyno-tuned boost/fuel maps. They will also re-map the timing curves, maximizing horsepower and reliability. Priced at $600 for initial computer, $100 for any changes desired. Requires purchase of AFM with harness, Injectors and dropping resistors. The Jim Wolf package is by far the easiest way to increase boost levels on a turbo Z, however the tune offered is very conservative to allow for some margin of error. It will provide correct fuel and timing for about 450 crankshaft HP.

JIM WOLF 450HP (4BAR): This package uses the same configuration as above, but with a higher (4-bar) fuel pressure. Some low boost MAF resolution is lost in favor of high boost performance and fueling capacity. This system has been used on cars making 450+RWHP with good results.

This section could (and probably will) be an entire FAQ in itself. The stock T3 turbocharger is dinky; the T25 is an even smaller hair-dryer of a turbocharger. Neither is actually very well suited for a 3.0L engine at anything too much over their stock boost settings. The motivations for using a small turbo to start (T3) with and then going even smaller (T25) were obvious; Nissan gladly traded power for response.

TURBOCHARGER UPGRADE; ONE OF THE MOST IMPORTANT DECISIONS YOU WILL MAKE:

Basic 300ZX turbocharger information:

Absolutely, before you do anything, read How turbochargers work; this is a basic explanation and will get you started nicely. If you are interested in a little more detail, practical applications and cool pictures, buy Maximum Boost by Corky Bell.

Notice the difference? The left is the 88-89 T25 and the right is the 84-87 T3.

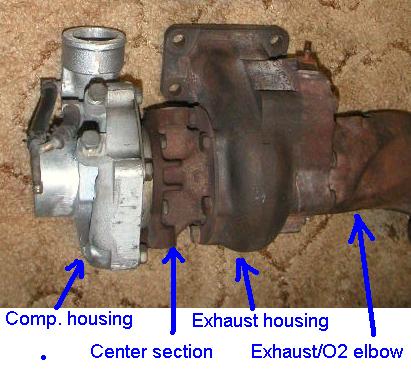

Note the components of a typical turbocharger.

Note the 7-bolt Nissan-only exhaust turbine housing vs. the "Ford 5 bolt" standard housing.

After reviewing the preceding pictures, you can understand why people may have a hard time upgrading their turbo. The stock turbine housing needs to be used in order to retain the wastegate/O2 elbow that bolts onto it and the down-pipe. You can send the turbine housing out to get bored out larger for use with an upgraded turbine wheel, at a slight loss of turbine efficiency. If you want another turbine housing, there's just more work involved. First, decide if you want to go with an internal or external wastegate. (see External Wastegates ) Secondly, fabricate an elbow off your new turbine housing to the existing downpipe (don't forget to weld in an O2 bung). 3" pipe has been used to fabircate such elbows, but clearance to the steering shaft is somewhat close.

Selecting a Turbocharger:

At this point you need to decide what 'kind' of a car you are going for. In general, the larger a turbo is the more efficiently it can move air into (and allow air to move out of) your engine. Unfortunately (also in general) the larger you go, the more "lag" you will have and the higher in RPM your engine will have to be to "spool" the turbo. Do you want super-fast response and low-rpm spool? Do you want gobs and gobs of power? Do you want something in between? What other modifications do you plan to do in the future (if any)?

Larger turbos can flow more air, changed compressor/turbine blades can increase boost response and still flow more air. There are many, many turbo manufacturers and retailers, most are able to get you a customized and upgraded, as well as rebuilt rebuilt, stock turbo. The most popular upgrade is usually a Garrett type ‘hybrid' turbo. Consisting of a T3 turbine section mated with a T4 compressor section, these keep the boost response similar to a T3 while having the compressor flow of a T4. There are many types of T4 compressors and T3 or T4 turbines to choose from, and some information on selecting a compressor for a VG30 can be found here.

Holset turbochargers factory installed on Cummins diesel trucks have started to become popular. HX35 and HY35 are a good sized upgrade, but will require slightly more extensive modification to install as compared to a Garrett turbo. The turbine housing flange is the same as a T3, but they use a v-band exhaust exit and different oil fittings. There is information regarding the models and method of installing a holset turbocharger on your 300ZX here. (regestration required on Z31 Performance forums)

The intricacies of different turbo options is way beyond the scope of this FAQ; it could actually be a FAQ in and of itself. Contact a reputable vendor and explore your options, but remember that you can't have everything. If you want lightning fast spool, you won't get 400HP flow capability. Ballbearing turbochargers, while expensive, do offer a slightly faster spool time and lower RPM than conventional journal bearing units. If you want 600HP from your built engine, just don't plan on having any boost until at least 3000RPM (with out spending gobs of money on a variable turbine turbo).

Selecting a Wastegate configuration:

How much you want to spend, and how much work you want to do will be the deciding factors in what wastegate setup you go with. Many people stay with an internal gate and have the turbine housing bored out for a larger turbine wheel (Turbonetics inc. does this for $100). If you port the internal wastegate hole and use a strong enough actuator, the Nissan internal gate will be able to provide stable boost control at high boost pressures (mine holds stable at 24PSI with a stock actuator re-enforced with throttle return springs). Do realize that even bored out and with a larger turbine installed, the stock housing (.63AR) is still going to be more restrictive than most aftermarket housings designed for the larger turbine.

Prices range from $400 to $5000+ depending on what type of turbo and

wastegate are selected.

More vendors than can be listed: Majestic Turbo, AZ Turbo & Tractor

Supply, Turbo

This section is for people whom are up to doing modifications beyond the 'basic' bolt-on. With the above modifications in place, most cars should easily be making 360-400RWHP on pump gas.

COOLING:

RADIATOR: The stock turbo radiator is a very good dual-core unit, and if the cooling system is in good condition it should be more than capable of cooling a high-performance engine. The primary reason most people have to ‘upgrade’ this component is for space as well as ease of intercooler pipe routing and mounting. A popular unit is the Afco because its inlet and outlet are located very near the routing of the stock radiator hoses.

ENGINE OIL: It is my personal belief that all turbocharged cars used in boost for any real amount of time (20 seconds or more) should have an engine oil cooler regardless of the oil type used. This is especially true if you plan on doing any track-type racing. 300ZX Turbo cars that were used in showroom stock racing would frequently overheat their oil. There are many brands and types of oil coolers available, research this on your own. Synthetic oil can also be considered an alternative to an oil cooler because they are able to handle much higher sustained temperatures than regular oils.

FAN: The engine cooling fan is driven off of the water pump pulley which is driven off the crankshaft pulley. Installing an electric fan will directly decrease drag on the engine. The fan should be triggered by a water temp sensor, so it will only turn on (and rob power) when necessary. In fact, I really doubt the fan is useful except when idling. When in motion, the fan is basically pointless. Note here that the draw rating of a large fan could be as much as 15 amps. This can cause some more strain on a poor condition alternator/charging system. Make sure your alternator is up to snuff or upgrade to a Maxima alternator before installing an electric fan.

TRANSMISSION: I'm not trying to get into driveline stuff here, but if you have a stock automatic transmission, it’s very doubtful that you will have a working one for very long at these power levels. LevelTen and KEAS build these same Jatco 4N71B automatic transmissions (and sell individual components) that will hold this kind of power. Installing a transmission dedicated is a good idea, and fortunately it is very easy. Almost any cooler designed for engine oil or transmissions will work, but bigger is usually better. It can be mounted behind the radiator, but for best cooling it should be in front of the radiator (behind the intercooler) if it will fit.

MORE BOLT ON PERFORMANCE:

ADJUSTABLE CAM GEARS: Gears that change cam timing to be more optimum for a certain RPM range. In general, advancing cam timing will result in low RPM performance, while retarding cam timing will increase top end power. Vendors:

CRANK SCRAPER: A rigid metal sheet that is cut to to fit close to the crank as it rotates. This reduces windage in the crankcase and results in less parasitic power loss. Simple installation between oil pan and engine block. Only small power gains at high RPM operation should be expected. Currently the only known vendor is: http://www.crank-scrapers.com/

THROTTLE BODY: Will not make a difference on a car with a stock sized intake pipe or a stock

upper intake plenum. A unit off a Nissan KA24E/DE engine (such as the engine in

the 240SX and Stanza) will bolt on to your stock plenum. The plenum must be

ported out to the size of the larger throttle body for it to make any difference

at all.

PRICE: ~ $40-50

UNDERDRIVE/LIGHTWEIGHT PULLEY: Unorthodox racing underdrive pulleys (pic) are the only type I am aware of, and as of 2005 they have been discontinued. A limited supply still exists, as their remaining stock was purchased in 2005. If you can find one, expect to pay $100-200. These are only available for 84-86 cars which use v-belts for both AC and power steering. Early 87 engines can swap to the earlier setup, but be aware that this means changing both your AC compressor and power steering pump (the pulleys on these components will not interchange with the earlier versions). The lighter weight and underdrive nets a claimed 12HP on a stock turbo car. Be aware that if your alternator is strained (from something like a high power stereo system) or not in good working order, this modification can make it even worse. There is also an ongoing debate about the costs of removing the harmonic balancer. I have not to date heard of any failure relating to the removal of the device designed to balance the harmonics of the rotating assembly. Automotive theory suggests that there are frequencies generated in the typical engine that can damage, if not outright break otherwise solid components. By all means, research this topic on your own.

ALUMINUM FLYWHEEL: While this is also a driveline modification, it can result in slightly more horsepower to the wheels. The real benefit is faster acceleration of the engine due to the lessened requirement for energy to accelerate the rotating assembly. This makes a difference in lower gears, allowing faster engine acceleration and quick rev-matching. The down side is the loss of stored rotational energy, which can result in less powerful launches and more difficulty taking off from a stop at low RPM. Fidanza aluminum flywheels come highly recommended and will work with all Z31 pressure plates and clutch discs; including both 84-86 and 87-89 turbo. The Fidanza flywheel (pic) is 11lbs compared to the stock 20lbs.

REMOVING A/C SYSTEM: Yet another possibility for a couple extra horsepower, along with 50 or so pounds less weight in your car.

UPGRADED IGNITIONS: If the Z31 had a poor ignition system I would recommend it, but the stock Z31 ignition is very good. There is really no need to change it unless you have a turbo car making 400+RWHP and are experiencing high-boost/nitrous misfires. Stock ignition systems been used on many other cars making 400+RWHP without issues when smaller plug gaps are set (.028-.032 seems a good low range). If you do decide you need to upgrade, go with a good quality ignition system, (MSD, Accel, Jacobs) with a rev limiter and don't expect any miracles. Remember most units require a tachometer adapter to keep stock tachometer functionality.

SPARK PLUGS AND WIRES: Standard plugs are all you will need, regular NGK copper plugs are what most people use because of their good performance and long life. There are many different spark plug designs available on the market, a few of the more common ones are:

· Standard Copper plugs: speak for themselves; the industry standard plug design.

· V-power/split electrode: Not much difference, pretty much a standard plug with a split electrode. Don’t bother with these.

· Platinum plugs: Do NOT work very well with turbocharged engines, not recommended.

· Iridium plugs: Are suitable for turbocharged cars and can yield small performance gains, but are reported to have a very limited lifespan compared to standard plugs.

· Race plugs: These are plugs with a much smaller electrode which are designed to have a minimal “hot spot” and thus work better in race applications. Much shorter life than standard plugs, they also do not have a resistor in order to maximize spark potential; for this reason they can cause electrical interference with things like your radio.

The real important things to consider with spark plugs are the heat range and gap setting.

Heat range is essentially how quickly a spark plug conducts its heat to the head; a higher number means more conduction and a colder plug overall. If you are running high boost, switch to a one heat range colder plug (stock is 6), this may help prevent detonation. A good rule of thumb is one head range colder for each additional 100-150HP added to the engine over stock. (NGK spark plug numbering scheme)

Gapping plugs correctly in a high performance engine is critical. If you have a stock ignition and are running high boost on an aftermarket turbo, you may want to gap your plugs down as low as .028. Stock gap is .039-.043, and is on the high side for good emissions and performance with a stock engine at stock boost.

Plug wires are a subject of amazing hype. The idea here is getting as much spark energy to the plug as possible, with minimal losses to resistance along the way. Many companies will claim bigger wires are better, which is not the case. The one advantage to buying a new set of quality OEM or aftermarket wires is you more than likely won't ever have to replace them again. Highly recommended are OEM, and NGK plug wires; they have been reported to have the best fit and overall quality. Accel, MSD and Magnecor are some "high performance" brands to consider. For real data regarding plug wires, consult the Magnecor website here.

NITROUS (GIGGLE GAS):

Nitrous is a very legitimate way to make gobs of cheap horsepower. Nitrous and turbochargers work very well together if the system is tuned properly. For some reason, nitrous has been given a bad reputation it never deserved. Almost all the problems associated with nitrous can be explained by one sentence: NITROUS DOES NOT BLOW MOTORS; IDIOTS WITH NITROUS BLOW MOTORS. Like any other modification, nitrous must be well planned and installed correctly. Most basic wet kits are ~$500 from a reputable vendor such as Nitrous Oxide Systems (Holley), Nitrous Express, ZEX, etc.

Nitrous systems: Wet, Dry, and Direct port

CUSTOM MANIFOLDS:

[8.0] MODIFIED ENGINES:

HEADS (TOP END):

CAMSHAFTS: Aftermarket cams are a very good way to make additional power for a relatively inexpensive cost. Cam degreeing, lobe seperation and lift all effect how an engine operates over its usable RPM. On turbocharged cars especially, cam selection can greatly change the driving characteristics of your engine (generally for the better). While regrinds have a bad reputation among some people, I have never heard of a failure related to the reground cams being used. As far as cams go: if you've already built your car up to this point and you don't care so much about low end power, go big and don't look back. When putting in aftermarket cams, it is recommended that you also resurface your lifters and install upgraded valve springs, see below for more information. Note on regrinding process: when a cam is re-ground, no new material is added to the lobes. Rather, the base circle of the cam lobe is cut smaller. For speculative purposes, if a cam had a lift of .300” and a lift of .340” was desired, .040” would be removed from the base circle and the peak of the lobe would be left at the same height. The base circle is reduced only as much as is needed to accomplish the desired degreeing and lift for your new cam grind. How is this extra “slack” from the smaller base circle taken up? Hydraulic lifters have more than enough adjustment range to make up for this loss of base circle diameter automatically. As far as lifters go, you can either buy all new ones for around $120 or resurface yours. You can have a machine shop resurface the lifters, or you can do it yourself with some very fine (1000+ grit) sandpaper. Simply place the sandpaper on a very flat surface and rub the cam surface of the lifter across it, rotating it 10 degrees or so per pass across the paper.

Camshaft Info/Specs Page (link)

Regrinds run about $200, Schneider racing, Web, ISKY, Paeco, etc.

New billet cams are $400+, Nissan Motorsports, JWT.

VALVES AND VALVE SPRINGS:

Valves: The popular valve brand of choice for SOHC VG engines is Ferrea. They make two types of valves for the VG30ET in both stock size and 1mm oversize. Ferrea produces top-of-the-line competition-grade valves for almost every popular engine. The primary advantage to quality aftermarket valves is their higher heat tolerance, meaning smaller seat sizes can be used to gain additional flow. The valves themselves are also shaped slightly better for flow to begin with; Ferrea valves also have a cut along the edge of the valve face to further promote good airflow.

Super Alloy/Competition Plus, Stock size: F1843P (in), F1845P (ex)

Super Alloy/Competition Plus, 1MM oversize: F1844P (in), F1846P (ex)

More information can be obtained on the Ferrea website.

Please note that oversize valves require cutting the seat inserts larger along with additional port modifications to realize any benefit at all.

For reference purposes, I weighed my stock size Ferrea super alloy valves against some lightly used stock valves after a good cleaning:

Stock Intake Valve: 81.2 grams

Stock Exhaust Valve: 78.6 grams

Ferrea Intake Valve: 79.2 grams (2.0 grams, 2.5% lighter)

Ferrea Exhaust Valve: 76.8 grams (1.8 grams, 2.3% lighter)

Valve Springs: Most aftermarket valve springs will be advantageous in two ways: Higher rate and higher lift before coil bind. Valves can “float” when the spring rate is insufficient to keep the valve-train mass in check during high-rpm operation. That is, the valve itself will actually remain open during the compression stroke because the spring is too weak, this causes the lifter to “fly off “ the lobe of the camshaft and then (when the valve does close or the lobe comes back around to the lifter) collide with one another in a very unkind manner. Obviously you can see why a higher lift camshaft will have a steeper ramp on the lobe and hence a tendency to “throw” the valve-train components even more. The higher rate valve spring (and/or lighter valves) will keep the lifter in contact with the cam lobe during high-rpm operation. Note: Good condition stock double valve springs have been used up to 7000RPM with stock valve springs and cams. Schneider Racing and JWT sell aftermarket valve springs for the VG30 (L28's also use the same springs).

HEAD WORK AND VALVE GRIND:

Head porting on SOHC VG engines is often overlooked or dismissed by the ignorant as not being worthwhile, head porting is a very viable means to produce additional power. Without going into extreme detail in this area, I can say that our exhaust ports are among some of the worst I have seen (IE: there can be very large gains here). The short side radius of the exhaust port entry is plain awful. The valve guide bosses extend into the port with a rather poor shape and hence cause very turbulent flow. On some heads I have seen more nasty casting marks in the ports than you can know what to do with. The short: you can expect 20+hp at high rpm from a basic head porting job, and even more with some time on a flow bench.

Combustion chamber polishing is not actually changing the shape of anything in the combustion chamber at all, rather it is just smoothing all of the surfaces to a mirror-like shine to prevent carbon buildup and hot spots. The sharp edge around the bottom of the head in the combustion chamber should be very lightly rounded to prevent hot-spots from forming on it as well.

Valve grind refers to the size and angles of the cuts made on the valve and the valve seat insert in the head. Most people do not understand the difference between a valve seat and a valve seat insert. The seat insert is the component that is pressed into the head. This is the part that the valve seat (the area of the seat insert on which the valve seals) is actually cut, not the seat itself because the seat IS the cut. Again, I don’t want to spend hours explaining the basics here when you can just buy a book and read it for yourself..

Valve seats: The basics are that the bigger the valve seat size is the longer the valve seat will last and more heat can be transmitted out of the valve and into the head when it is closed. Smaller seats usually create better flow at low valve lifts; because the valve spends most of its time at low lift, the seat size and angles into and out of the seat (called a 3-angle grind) needs some careful attention.

Valve/seat grind: The stock grind is a 3-angle with a fairly large seat designed for a long lasting valve seal. In addition to the seat size, the angles can be changed as well as the number of angles. 3-angle is by far the most common grind, but 5-angle and radial blend are also options depending on where you take the heads to be done. A 5 angle adds two additional angles to the seat insert in order to further smooth flow past the seat. A radial blend is a very labor-intensive process of hand-blending in the edge of the two angles on either end of the seat insert to have a smooth radius; due to this is amount of labor for a small gain, this usually only done in race engines. When you call shops asking about valve grinds, be sure to ask what type of machine they use. SERDI machines and cutters are the industry standard for cutting valve seats, there are also other types of carbide cutters that are very similar to, and can do almost as good of a job, as the SERDI can. Some shops have a vast assortment of angles to select from and can make recommendations for you, some only have a very few to do common jobs on commuter cars. Stone grinders are cheap and effective, but are considered vastly obsolete compared to today’s high-tech seat cutting technologies.

Back-cutting valves: This is the process of placing an additional cut (outside of the cuts used in the valve grind) on the backside of the valve. This has been shown to yield 5-8% flow increase in most engines and at ~$3-5 per valve, is probably a good idea for a street performance engine. (note: VG30 exhaust valves already have a small 1/8” back cut from the factory)

Swirl polishing: The backs of the valves and tulip are swirl polished. While this looks very nice, it does not do very much at all for airflow. One benefit is that if they are polished to a near-mirror finish, it will prevent carbon deposits on the valve.

Stem cutting/guide boss removal: The stems of the valves that extend into the port are trimmed down to a smaller profile to make them have a small profile in the port. Guide bosses can be removed from the ports entirely. Both of these modifications will cause the valves temperature to skyrocket during operation under boost, so again these are modifications reserved for race engines only.

Oversized valves: Larger valves are installed into the heads, and the seat inserts are cut out larger or replaced with larger inserts to accommodate the larger valve. This must accompany careful modification of the ports and combustion chamber to achieve real gains in flow. Valve shrouding by the sides of the combustion chamber is a big problem for flow, and only slight modification of the combustion chamber is needed. The chamber on our heads is already fairly well designed; don’t think you can do a better job than has already been done.

Valve guides: If they are within specs, stock valve guides are very good and have a good level of heat tolerance. Extreme-duty copper or manganese bronze replacement guides can be special ordered through most engine shops, provided they want to take the time to do it for you.

Exhaust manifold studs or bolts: The stock studs (m8x1.5) have a chronic problem with breaking, even with bone-stock motors. There have been several part revisions on the studs ever since the engine was released in 1983. When the VG33 was released, Nissan finally ‘fixed’ the problem by simply using larger (m10x1.5) studs. If your heads are off, it is highly recommended that you replace the studs with either new stainless studs or new high-grade stainless bolts. Studs will be stronger than bolts, but if the bolts do happen to ever break (which they most likely will not) they will break near the head and be easy to remove.

HEAD GASKETS, O-RINGS AND HEAD STUDS:

· Head gaskets: The metal units formerly made by HKS and GReddy are no longer available, but stock head gaskets have been shown to hold at 30PSI of boost pressure. There are some brands (such as Victor-Reinz) that come very close to meeting OEM quality; I highly recommend not using Fel-Pro head gaskets for your VG30ET. There are generally two types of aftermarket head gaskets on the market: Stainless steel and copper. Stainless steel multi-layer head gaskets will hold any amount of boost and can most likely handle more detonation than your pistons and heads can. They can also be re-used multiple times if they are in good condition. Copper head gaskets are designed to be used with a o-ring which is installed in the block around the bore. Do not use o-rings with stock head gaskets. OEM head gaskets: $40 each, Copper: ~$150+, O-ring block: ~$180+, Stainless Steel Multi Layer (if you can find them): $400+ used.

· Head studs: Replacing your stock head bolts with stronger forged studs that can be used with a higher torque setting than stock head bolts. Even though our (13) stock head bolts (per head) have been used on many high powered engines with great success, many people insist on using aftermarket parts. ARP is the industry standard in aftermarket bolts and studs. Their world-class products are used in everything from 700HP drag Hondas to 5,000+HP nitro funny cars. ARP has no listed head stud “kit” for the VG30ET, The ARP part numbers than can be used (as reported by a board member) are as follows:

M5-100-1LB - Short Stud

AM5-900-1B - Long Stud

AMW-750N - washer (26 needed)

AMN-12-1 - nut (26 needed)

ROTATING ASSEMBLY: CRANK, RODS, PISTONS, ETC (BOTTOM END):

Useful weight info for comparison (submitted by a Z31.com board member):

CONNECTING RODS: To kill the rumors here and now, stock VG30ET rods ARE forged. In fact, Nissan has used forged rods since the L24 engine in the 240Z. VG30DETT rods are also forged, but are almost the same as W-series ET rods aside for being slightly heavier (and perhaps slightly stronger?) and having a larger wrist pin. I have never seen a Z31 rod failure that was not the fault of another component failure that ended up taking the rod with it (bearing, pin, piston, rod bolt). That does not mean it won't happen, even the very best forged rods can fail. There are two kinds of VG30 rods, the “former” (non-w series) and “modified” (w-series). The non-w rods have (very very slightly) bigger press-fit pins that float in the piston only. The w-series rods have “full floating” pins that float in both the piston and rod. Z32 and eagle rods have a ~1mm larger wrist pin than Z31 rods. Be sure you know which rods you have or plan to use before you buy pistons.

Aftermarket offerings:

Eagle “ESP” H-Beam Forged rods (include ARP rod bolts) ~$600, 580 grams.

BRC Performance custom forged connecting rods ~$1000, unknown weight.

Pauter Custom Forged Rods ~$1000, 625 grams each.

Carrillo Forged Rods ~$1000, unknown weight.

Others?

PISTONS: All Nissan VG engines have grade 1 quality cast pistons. Yes, Z32 pistons are also cast and will give you no benefit over Z31 pistons (except for lowering the compression ratio). There is some debate over what power level they fail at, but there is consensus on two things:

1. The pistons are always the first component in the bottom end to give out.

2. The ring land area is what breaks 90% of the time

Many people have run stock pistons at 450-500RWHP with no failures. Some people break pistons with as little as 300RWHP. It all has to do with the engine in question, the revolutions it is seeing, the amount of timing being run, and detonation. Even small amounts of detonation can destroy stock pistons quickly, be careful. (Personal note: when I was tuning one of my Z31’s, I heard some light detonation on a few occasions, mostly from not allowing enough cool off period between pulls. In several years of beating on the engine, I never once broke a piston ring land. There is no doubt in my mind that heavy or prolonged detonation will destroy spark plugs, head gaskets, and pistons. The mere fact that detonation did not damage anything at this power level is testament to the strength of Nissan cast pistons.)

Aftermarket offerings:

J-E Forged pistons (designed for Z32): 9:1 or 10.5:1 compression ratios for Z32's, works out to roughly 8:1 and 9.5:1 with Z31 heads. Designed for Z32 pin diameter.

BRC Performance custom forged pistons: Any compression ratio desired, custom made to order.

Ross custom forged pistons: Any compression ratio desired, custom made to order.

Arias custom forged pistons. Any compression ratio, custom made to order. Very affordable prices!

Many others.

CRANK: The VG30 crank is not forged, it is nodular iron which is at a strength level between that of cast and forged. Regardless of not being forged, it still holds plenty of power. Many VG30 powered cars have horsepower numbers in the mid 700’s at the wheels using a stock crankshaft. I don't know of any individuals whom have managed to break VG30ET cranks from excessive power loads, but it has been said that Electramotive did with development of the VG for the GTP glass racing.. You can have a custom billet crank made for $2500-3000, but at that point you might be better off buying another engine for that “wow factor” discussed earlier.

The VG30DETT crank is forged, and speculated to be stronger. Nobody has yet provided any evidence that installing this crank is worthwhile, but it can and ahs been done with the help of some machine work on the crankshaft snout fit in the VG30E block.

It has been recommended that you not have a Nissan crankshaft reground unless a replacement crank cannot be sourced. The reason being that grinding a ground grank will usually not have the lifespan of a good stock unit due to the bearing clearance differences. Most people cannot grind a crank much more accurate than .001", which is the entire range of OEM grades (about .0004" each grade).

BEARINGS: It is recommended to use Nissan OEM main bearings of the correct grade (stamped on the crank and block). Again, this is another part in which I have never heard of a failure (that was not related to oil starvation at least). Many people have used Clevite77 and other high performance bearing sets.

· Main studs: ARP makes a replacement main stud

kit which is listed as part number: 202-5402 This is also the same kit used for the SR20DET engine, and it has been debated that the main studs are actually different from VG mains and the nut runs into the shank when fully torqued. Others have had this experience, while I have not. You can use the following part numbers to make your own "better" main stud "Kit" (thanks to Kyle Ellis for providing this information):

200-8510 washer, x8, ~$.80 ea

200-8605 nut, x8, ~$.66 ea

ATP4.650-1LB main stud, ~$7.66 ea

· Rod Bolts: The ARP (high performance) rod bolts are a recommended replacement for the stock bolts if you plan to use any stock Nissan rods. The ARP part number for the Z31 rod bolt kit is: 202-6003 and for Z32 rods it is 202-6004.

A NOTE ON ENGINE ASSEMBLY:

How long your engine lasts at power levels more than double stock is largely dependant on the practices of whomever is both machining and putting together the bottom end. Finding a competant machine shop can be a chore, as most builders just assemble to generic and loose clearances they are used to. Anybody building high performance engines should be able to tell you that the tighter clearances are to OE spec, the longer your engine will last. This is part of the reason VG engines not only last 300K+ miles when well kept maintained, but also easily handle more than two times stock power level. Read through the FSM sections on bearing and piston grading for a little better understanding. If you have doubts as to your own engine assembly skills or don't have the tools or knowhow, then find the best or most reputable shop you can to do it for you. A good engine builder should also be able to provide you with records of the measured clearance of every rod and main bearing. They should also be able to tell you what the piston to cylinder clearance is and the grit they used for the cylinder hone, as selecting both is very piston, ring and block hardness specific. If you have any doubts afterwards, you can easily plastigage the main and rod bearings yourself to determine if they are in spec.

INTERNAL LINKS (FAQ PAGES): |

EXTERNAL LINKS (INFO): |

| RECOMMENDED BOOKS:

Maximum Boost, By: Corky Bell How To Build, Modify And Power Tune Cylinder Heads, By: David Gollan How To Modify Your Nissan And Datsun OHC Engine, By: Frank Honsowetz How To Tune and Modify Engine Management Systems, By: Jeff Hartman Supercharging, Turbocharging, & Nitrous Oxide Performance Handbook, By: Earl Davis Automotive Engines: Theory and Servicing, By: James Halderman and Chase Mitchell |

|

If you wish to submit or correct information here, please e-mail roasttchicken AT gmail DOT com.

Last Revised: Feb 03 2006